Newspaper from The Port Huron Times Herald dated Sunday, February 20, 1938.

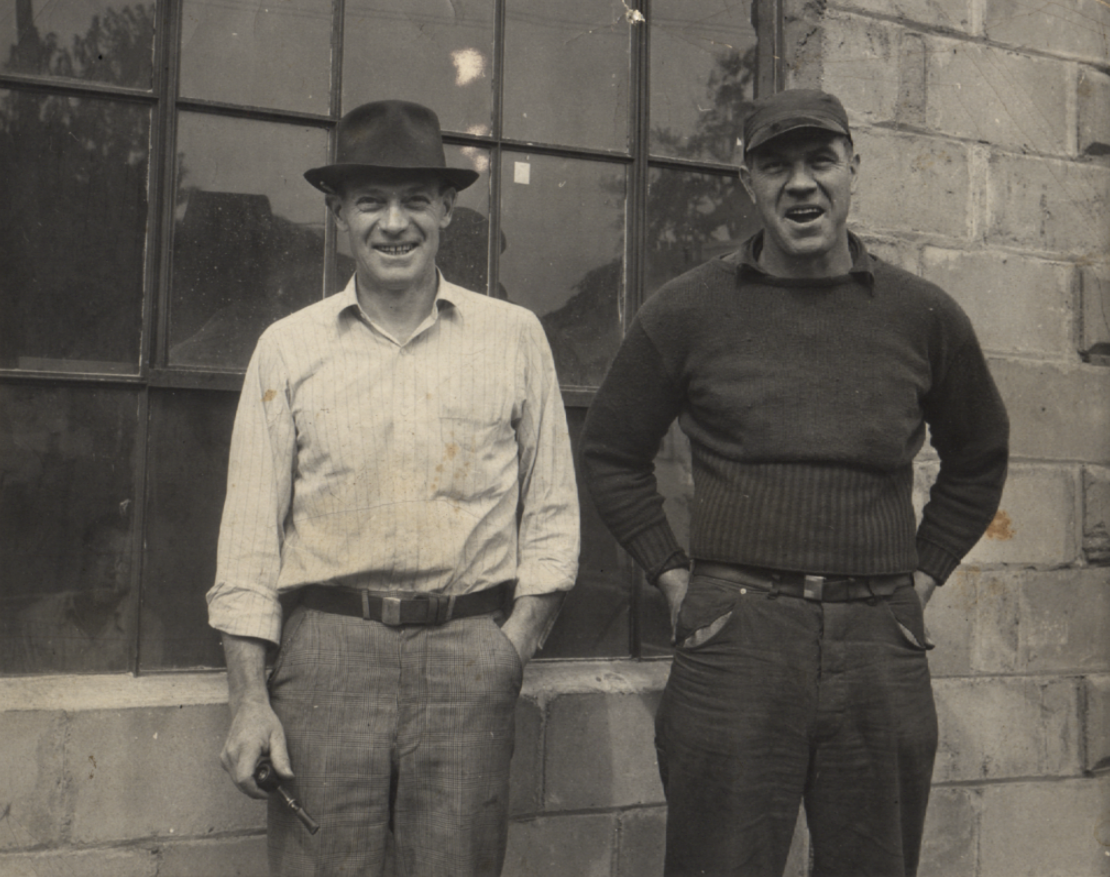

Captain William E. Warner, pictured right.

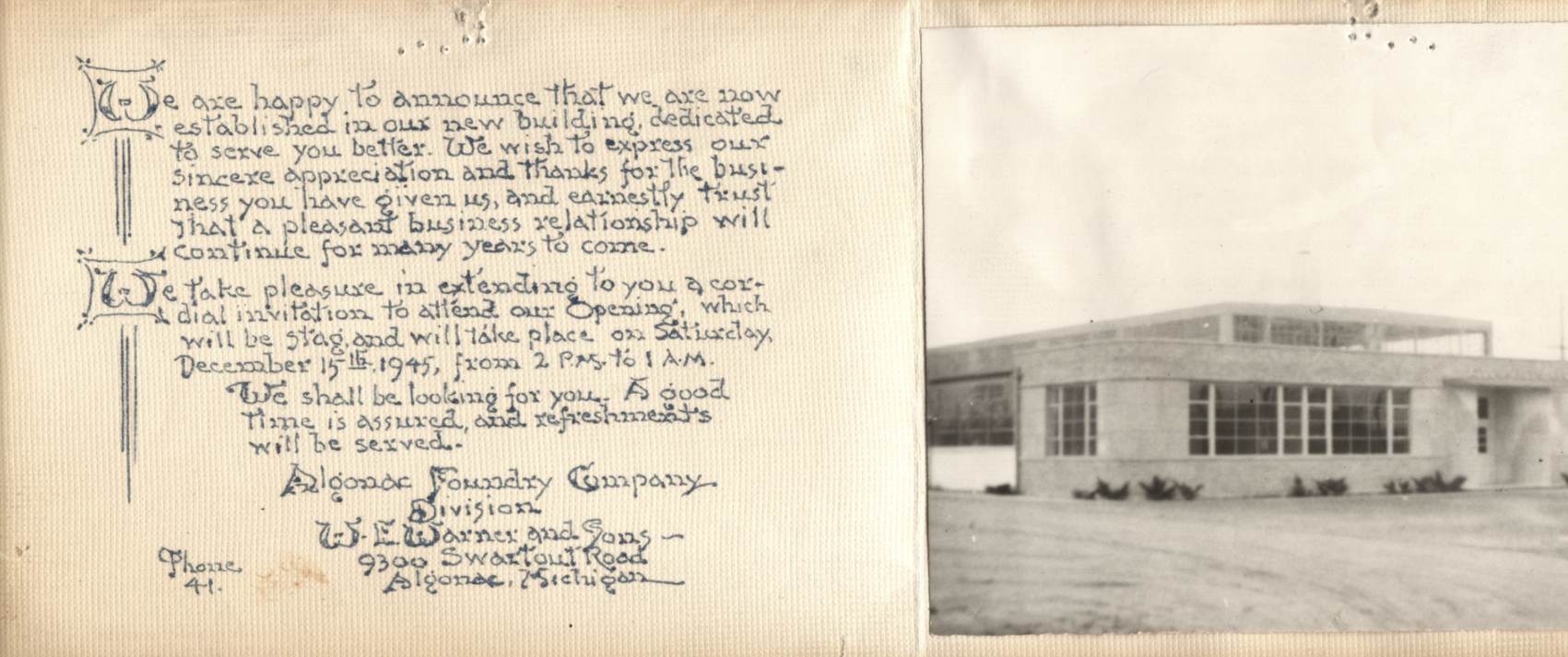

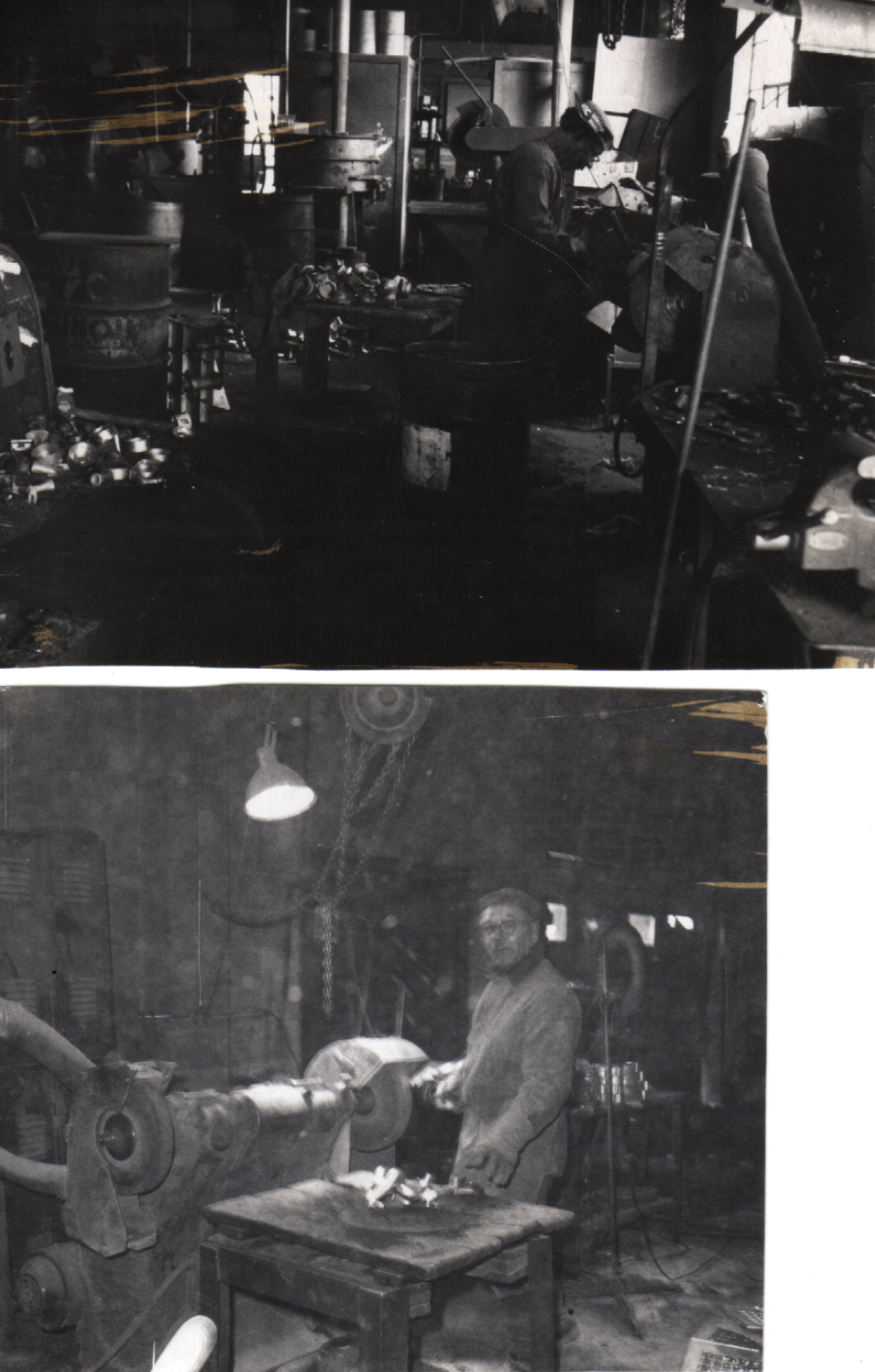

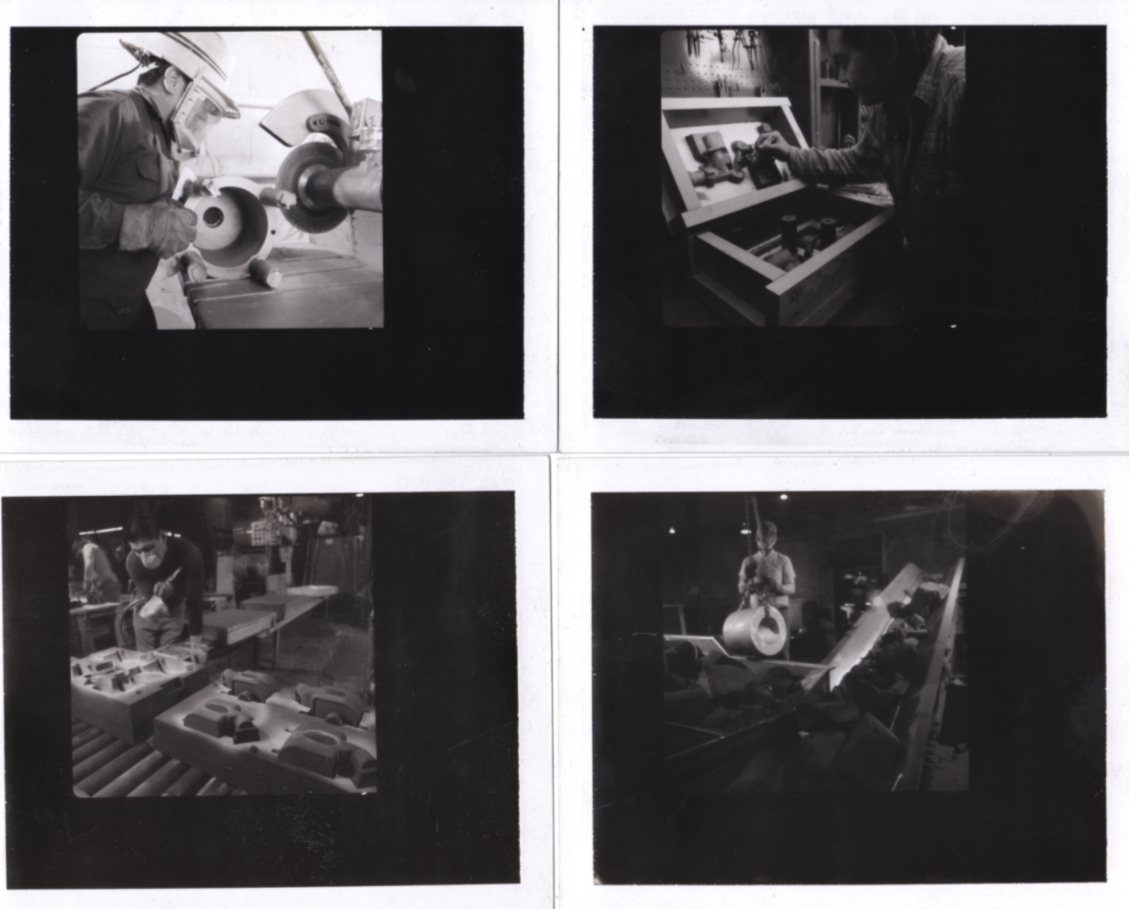

W.E. Warner & Sons, a building supply firm was established in 1911 by Captain William E. Warner, in order to keep his 5 sons on land. His sons were Ralph C Warner, Charles H.E. Warner, Vernon E Warner, Norman E Warner and Wilbert A Warner. In 1923 the foundry was added, to supply marine hardware to boat manufacturers, mainly Chris Craft boats. In 1946, the business was incorporated under the name of Algonac Foundry Company. The business later moved to a new larger building on Stone Road in Algonac.

Norman E Warner (Left) and Vernon E Warner (Right)

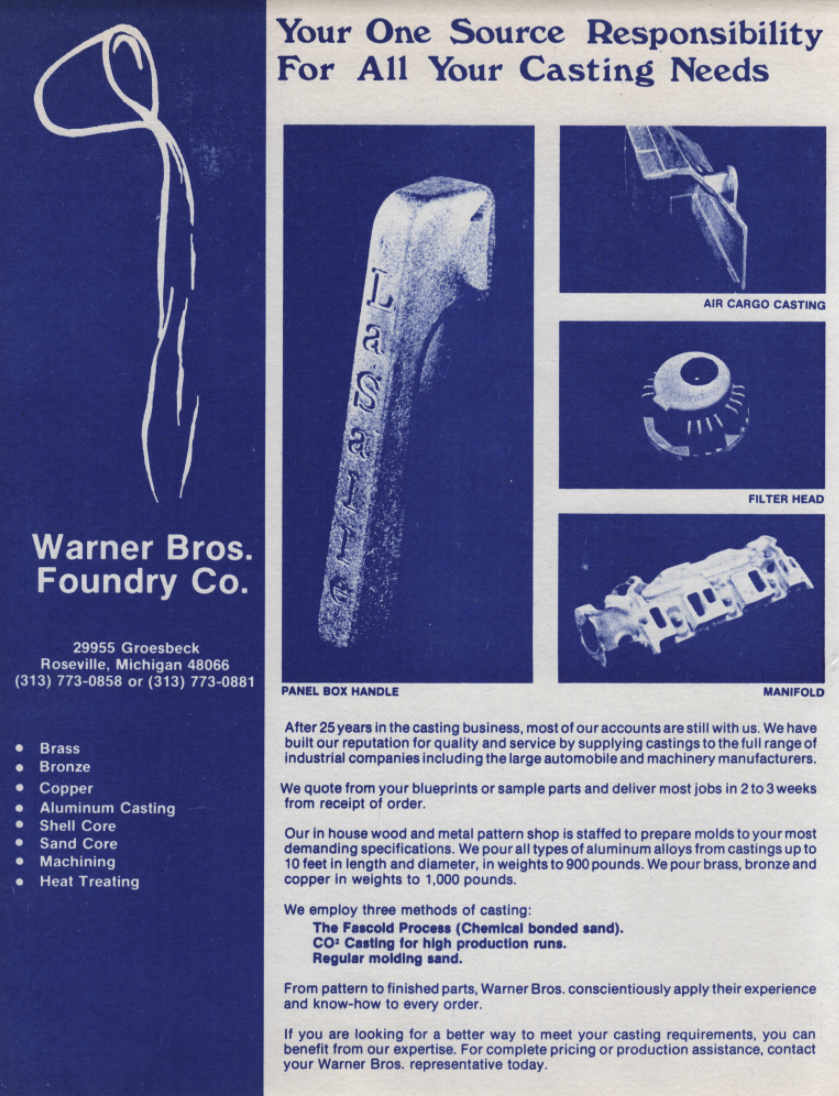

Lyle A Warner, son of Norman E Warner, decided to start a new foundry named Acro Cast, Inc. in 1955 that served beyond the marine industry. Acro Cast, Inc. later then changed it’s name in 1961 to Warner Bros. Foundry Company. The foundry then moved to its current building in the 1960’s located at 29955 Groesbeck Hwy in Roseville, MI.

The business was primarily using green sand molding. It later switched to a revolutionary new process, at the time, called air-set. Warner Bros. Foundry Company was the first company in the state to use and master this new process in 1974. The successful business needed to grow and was expanded, adding 3,000 sq ft to its current building in the 1980’s.

The foundry still remains in the Warner family to this day. The beloved founder Lyle A. Warner passed away in 2014. He made sure to pass on the years of wisdom to his son Lonn C Warner who runs the business now with his son Derek L Warner. The legacy of the Warner family is made of strong people. We strive to meet the expectations of Capt William E Warner, that the Warner family is made out of Iron.

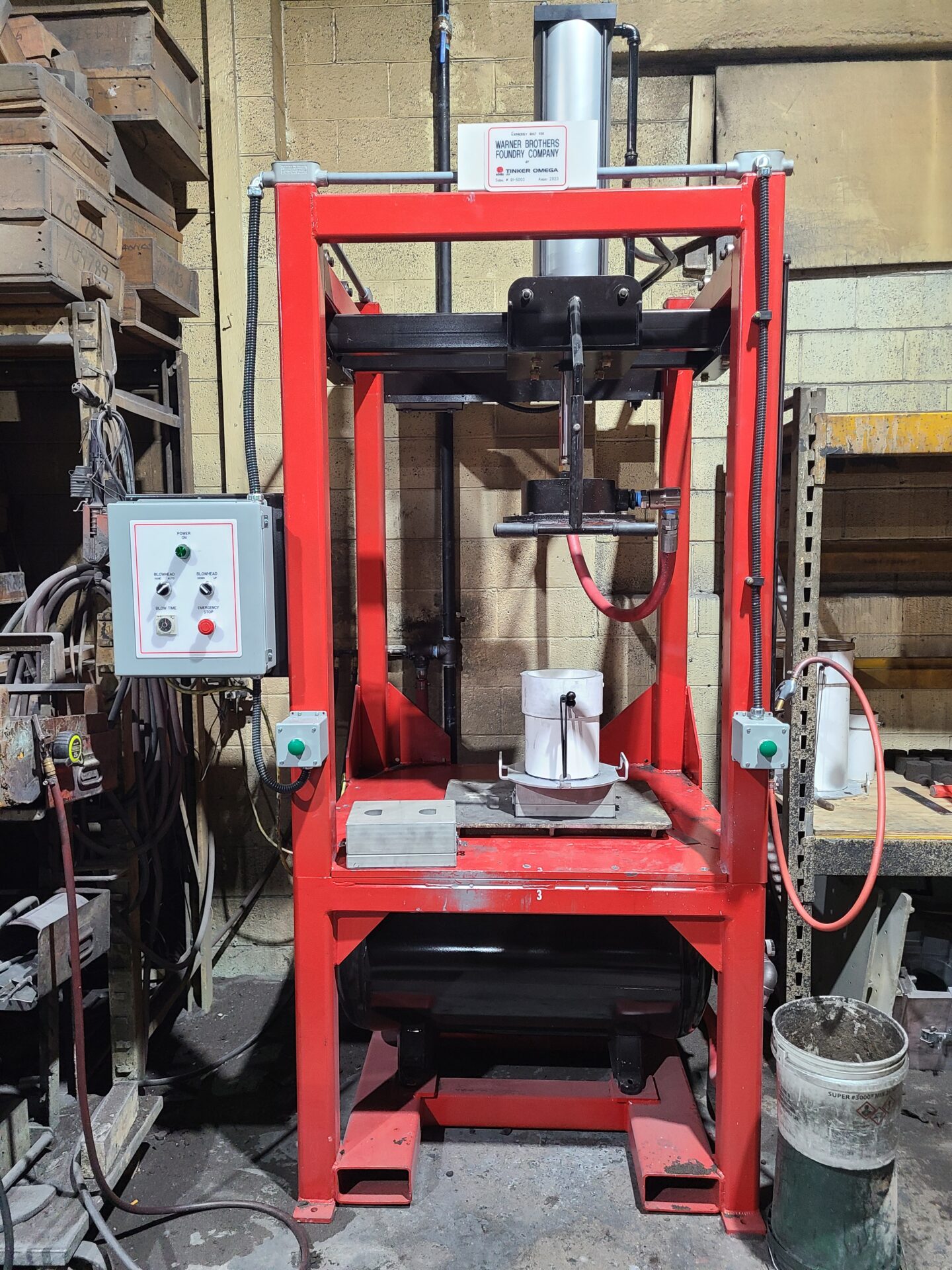

We look forward to seeing how the future Warner generations will continue revolutionizing how we work, and the equipment we use plays a major role. In 2023, we adopted new technologies to enhance our long-standing history of quality work. As we grow with this metal foundry evolution, we will only strengthen our legacy of exceeding customer expectations. Some of the casting technology advancements we’ve started using include the Goff 6 BB shot blaster and the NBBI-1 No-Bake Core System.

No-bake core shooters create more consistent cores that have improved densities and come at a lower cost than gas system cores. The no-bake process involves minimal tooling modification and reaches a high-volume blow pressure with easy adjustment. The NBBI-1 has a single blow head assembly clamp cylinder — its clamp force overcomes blow pressures up to 60 pounds per square inch. Those advancements mean we create precise molds that suit castings of many weights, sizes and shapes.

We’ve also added the Goff 6 BB shot blaster to our operations. With a direct drive blast wheel that turns at 3,600 rotations per minute, this new blasting equipment allows for maximum abrasive velocity, meaning we waste less abrasive media and save our customers money. This equipment includes numerous features engineered to reduce downtime, from easy blade replacement to an electric jam motor that minimizes the risk of damage to the tumble belt and liner.

The project managers and engineers at Warner Brothers Foundry are dedicated to continually pursuing industry trends to find the highest-quality equipment and materials. With our superior equipment solutions, we’ve built and maintained a reputation as a top casting company. We’re eager to see what future casting equipment evolutions will bring, and we’re ready to use that technology to further the foundry industry and our company history. If you’d like to learn more about what we do, browse our service offerings.

Get Started Today

If you’re interested in a custom solution, get in touch with us today for a quote!